- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2023-01-10 Origin: Site

Steel balls are indispensable in the bearing industry and the crushing industry. Qingdao Fuqin provide chrome steel balls, stainless steel balls, carbon steel balls and alloy balls. Although the steel ball is small, its load and life are very important in the transmission world, and its production process directly affects product quality.

Let's take a look at Qingdao Fuqin steel ball production process.

The materials of each specification and furnace number are inspected. If it is a wire, wire drawing is also required, and the wire is drawn to the required wire diameter with a wire drawing machine.

Under normal temperature conditions, the raw material is plastically deformed to form a spherical billet.

Remove the ring band on the surface of the ball blank, and at the same time increase the roughness of the steel ball surface, so that the ball blank is initially spherical.

Put the ball into the heat treatment furnace for carburizing, quenching and tempering to make the ball have a certain carburized layer and hardness, toughness and crushing load.

The surface quality and shape of the steel ball are further improved by fixing the iron plate and rotating the grinding wheel plate under a certain pressure for grinding.

Using two cast iron primary grinding discs, and then adding abrasives, through a certain pressure and mechanical movement, the surface quality of the precision specified by the process is achieved.

Using two cast iron lapping plates, adding abrasives, under the action of a little pressure and mechanical movement, some reserve is consumed to further improve the precision and surface quality of steel balls.

Using detectors and sorting machines and also100% hand picked to check and sorting steel balls. Photoelectric, eddy current, and vibration methods to select various defect balls, such as surface defects, shallow surface layer cracks, internal material defects.

The cleaning quality is improved and the damage to the surface of the steel ball is reduced through the spiral cleaning machine and the lifting turnover box, and the cleaning liquid is continuously circulated to ensure the cleanliness of the steel ball.

For each batch of steel balls, the final inspection is carried out according to the requirements of the process, such as the roundness, hardness, metallography, stress, etc. of the steel balls.

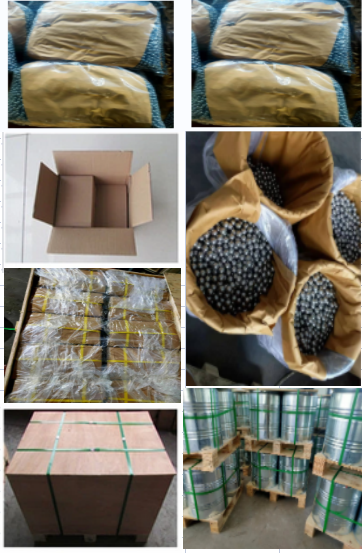

Qingdao Fuqin offer a variety of packaging services, according to customer requirements.Such as dry packaging or slight oil packaging; steel drums or wooden crates package.